For decades, alloy wheels have been lauded among the most popular/standard car tires – along with steelies. They are installed in almost every mainstream vehicle model; even yours might also be graced by their presence!

My insightful article will help lift some beginner confusion by diving into what an alloy wheel is and how it fares against other wheel types.

In this article:

What Does Alloy Wheels Mean?

The term “alloy wheels” means wheel rims produced with aluminum or magnesium alloys – sometimes even both. Due to magnesium’s essence in the entire manufacturing process, alloy wheels are sometimes titled “Mag wheels,” too.

A few decades ago, alloy wheels had not yet dominated the automobile tire industry as they currently are. Steelies were still considered the standard with decent durability, aesthetics, and strengths.

But as the demand for alloy wheels from motorsport companies dramatically surged, their prices started to get down, slowly surpassing steelies to become the crowd’s go-to option.

What Are The Benefits of Alloy Wheels?

Alloy materials themselves enjoy tons of benefits over other substances, which, in turn, also translates to major wheel advantages.

1. Aesthetic Appearance

At first glance, alloy wheels already attract attention with their sleek and stylish layout. Such visual appeals are partly due to their intricate manufacturing, which paves the way for more creative customization ideas.

Just put it next to any other wheel for comparison, and you can clearly see which one wins the round.

2. Performance

Looks are great, but certainly not the only offering these alloy wheels bring to the table. Their ability to improve car performance is also dutifully noted.

For one, they feel much lighter-weight than some of their counterparts (steelies, for instance), which plays a huge role in quicker acceleration, better braking, and improved fuel consumption.

Do not forget that every 10% weight reduction equates to a 7% increase in fuel economy! Your handling and precise steering will also enjoy tremendous boosts as a result.

A switch from steel to alloy rims has proved an increase in gas mileage on my old Hyundai Elantra. When the temp dropped to 50-60°F, the car only ate up 1-1.1 gallons (with alloy rims) to complete a 60-mile drive from my home to office, while that number jumped to 1.2-1.3 gallons when equipped with steelies at the same temperature.

Furthermore, the lightweightness helps limit tear and wear for common vehicle components, such as suspension, transmission, and engine.

Aided by the alloy’s impressive heat-dissipating nature, your wheels and profile tires will stay cool all day round and are much less subjected to premature defects.

3. Resistance to Corrosion

Alloy wheels are much more rust- and corrosion-resistant than other molten metals – which should surprise no one. After all, the exquisite material, stringent manufacturing, and slightly higher prices than some other wheels all have a purpose: they ensure your investment lasts for at least a decade.

Much less maintenance and replacement intervals are required as a result, saving you time, effort, and money in the long run.

What Are The Disadvantages of Alloy Wheels?

1. Struggling On Extremely Rugged Terrains

Most of the traditional steel wheels pale in comparison with alloy metals; that is for sure. But tougher, aftermarket steel wheels with added stability and buffers are a different story, doing much better than alloy on extremely rugged terrains.

Meanwhile, alloy can still be vulnerable to cracks and dents (though, thankfully, only after very long usage). Curb rashes might even pop up if your car has to travel through demanding or very poor road surfaces.

2. The Cost of Alloy Wheels

Repairing severely-damaged alloy wheels is not quite feasible, which leaves people no choice but to buy new ones (and that can be quite a budget blow).

Die-casting alloys are even more expensive since they must combine with some other premium metals for added sturdiness, such as nickel or magnesium.

The best way to avoid spending too much on alloy wheels is to keep them under regular maintenance schedules. I also suggest checking their condition at least once or twice every two months, which ensures any defects or dents (if any) are spotted before they worsen.

Minor alloy wheel damage for alloys costs very little, sometimes even cheaper than steelies.

How Are Alloy Wheels Made? 5 Methods In The Alloy Wheel Industry

1. Forging

This process is performed via one-step or multiple-step forgings of magnesium alloys (mostly ZK60 or AZ80). The results are often more pliable and tough than pure aluminum wheels, which unfortunately increases the overall costs as well.

More specifically, forging processes often involve at least one of the following:

- High-pressure application

- Hammering

- Rolling

- Heating

And sometimes a combination of all those. They aim to change the alloy’s crystal structure, manifesting stronger and lighter wheels.

2. Assembly

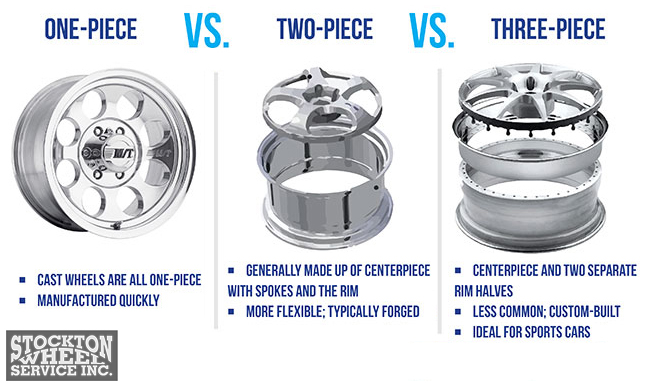

This production method produces one-piece, two-piece, or three-piece alloy forged wheels, with each piece being an original alloy billet.

- For single-piece wheels: the billet is converted into an entire wheel

- For multi-piece wheels: the billets transform into wheel parts

3. Die-Casting At High Pressure

As its name suggests, the procedure uses large-machine dies with high-closure force, ensuring they are tightly clamped. After that, a flurry of follow-up steps transpires:

- The wheel brands pour molten magnesium into filler tubes (called “shot sleeves”).

- The metal is pushed at high pressure/speed into the dies via a piston.

- As magnesium solidifies, the die opens to release the wheel.

Although such wheel-production methods can offer corrosion-resistance improvements and price reductions, their wheels are significantly weaker and less ductile – as expected of die casting at high pressure.

4. Die Casting At Low Pressure

Manufacturers often employ steel dies (arranged above molten-magnesium-filled crucibles) for low-pressure casting. At the same time, a pressurized cover/air gas mixture forces the metal into the dies via straw-like filler tubes.

When properly used, die casting at low pressure can offer the wheels more elasticity than most aluminum or magnesium wheels – though they still lag slightly behind forged magnesium ones.

5. Gravity Casting

Gravity-casting wheels have been around since the 1920s.

As it pours metal straight into the metal mold without centrifugal forces, vacuums, or pressurized gas, the tooling costs are extremely cheap, allowing flexible wheel design, short development timing, and small-batch productions.

Magnesium Alloy vs Aluminum Alloys Wheels: Which to Choose?

Magnesium alloys (especially those produced using the forging method mentioned above) can beat aluminum alloy wheel rims any day in terms of durability.

However, many drivers still place trust in aluminum wheels because:

- Availability: Aluminum alloy wheel purchases are much easier than magnesium. My team had to spend an entire week once trying to find a local store with available magnesium alloys.

- Handling: While modern, upgraded performance cars will work well with magnesium, regular vehicles for daily driving conditions still seem to benefit more from aluminum, as they enjoy better grip, traction, and a wide range of steering control levels.

Alloy vs. Regular Steel Wheel: Which to Choose?

Alloy, for sure. There are reasons why steelies are dethroned by alloy wheels.

The latter offers better fuel efficiency, longer-lasting shelf life, and powerful vehicle performance, making them the ultimate choice for drivers of all levels.

Aftermarket wheel dealers still offer some tough steelies with better power than alloy, but that is in exchange for quite an exorbitant price.

Conclusion

Detailed definitions, materials, and manufacturing processes for alloy wheels are thoroughly explored in this article, giving my readers insights into their performance and competitive edges over other wheels.

See more: Wheel vs tire vs rim

Consider the alloy wheel advantages, disadvantages (and, of course, the budget) to land on the best wheels on the market. Write to me if you need more help on this type of wheel.